| 产品物化性: |

<p>

<table id="table178" border="0" cellspacing="0" cellpadding="4" width="100%" height="1">

<tbody>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"><strong><font color="#0000ff" size="2"><span class="user3"><span style="FONT-FAMILY: 宋体">砂轮精密动平衡是精密磨削的秘诀! <br />

即使是普通的低价位磨床,也可使您的磨床加工达到最佳的精密要求! </span></span></font></strong></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"><font color="#666666"><span class="style11"><span style="FONT-FAMILY: 宋体; LETTER-SPACING: 1px; FONT-SIZE: 9pt"> 磨床是精密机械加工必不可少的工作母机,为了适应日趋精密的工作精度需求及不断追求的高效率和低成本的目标,全球的磨床制造业都在不懈地致力于:提高机床的几何精度,刚性和性能稳定性。</span></span></font>

<p><font color="#666666"><span class="style11"><span style="FONT-FAMILY: 宋体; LETTER-SPACING: 1px; FONT-SIZE: 9pt"> 众周知,砂轮是磨床的必要工具。想要让砂轮磨削出准确的尺寸和光洁的表面,必须防止磨削过程中的振动。砂轮的结构是由分布不均的大量颗粒组成,先天的不平衡无法避免,这必然会引起一定的偏心振动。而砂轮安装的偏心度、砂轮的厚度不均、主轴的不平衡及砂轮对冷却液的吸附等,会使振动更加增大。这些振动不仅仅影响到磨床的加工质量,还会降低磨床的主轴寿命、砂轮寿命,增加砂轮修正次数及修整金刚石的消耗等。 </span></span></font></p>

<p><span class="style11"><span style="LETTER-SPACING: 1px"><font color="#666666"><span style="FONT-FAMILY: 宋体"> </span></font></span></span><span style="FONT-FAMILY: 宋体"><font color="#666666"><span class="style11"><span style="LETTER-SPACING: 1px; FONT-SIZE: 9pt"> 我们的精密磨床在线动平衡仪器广泛的应用于国内的磨床 生产厂、零件加工厂客户。大力的感谢以下客户对我们的支持。</span></span></font></span></p>

</td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%">

<p style="TEXT-ALIGN: left" class="MsoPlainText" align="left"><span style="FONT-FAMILY: 宋体"><font color="#666666" size="2">宝鸡秦川机床厂 <br />

上海机床厂<br />

无锡开源机床<br />

深圳比亚迪汽车股份<br />

北京二机床厂<br />

济南四机床厂<br />

北京迪蒙特佳工具磨床<br />

济南华新如意机床<br />

宁波富尔肯密封件等等</font></span></p>

</td>

<td height="100%" valign="top" width="50%"><span style="FONT-FAMILY: 宋体"><font color="#666666" size="2">济南军区装备部 ? <br />

深圳富士康<br />

上海通用轴承公司<br />

台湾建德磨床<br />

上海通用汽车公司<br />

上海大众汽车发动机一厂<br />

重庆康明斯发动机厂<br />

重庆长安-铃木汽车厂<br />

长春一汽第二发动机厂等等</font></span></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"><span style="FONT-FAMILY: 宋体"><font color="#ff0000" size="2"><strong>传统手动砂轮静平衡校正工艺费时又费工且精度有限,并随着操作者技能水平不同,效率与效果差异甚大。</strong></font></span></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%"><img border="0" width="331" height="242" alt="" src="http://www.honfusen.com/yphoto.files/IMG0286A.jpg" /></td>

<td height="100%" valign="top" width="50%">

<p style="MARGIN-TOP: 0pt; MARGIN-BOTTOM: 0pt" class="p0"><font color="#666666"><span style="FONT-FAMILY: 宋体; FONT-SIZE: 11pt"> 砂轮是一个非均质的黏结体,旋转时因质心偏移回转中心而产生振动,严重危害研磨质量。</span></font></p>

<p style="MARGIN-TOP: 0pt; MARGIN-BOTTOM: 0pt" class="p0"> </p>

<p style="MARGIN-TOP: 0pt; MARGIN-BOTTOM: 0pt" class="p0"><span style="FONT-FAMILY: 宋体"><font style="FONT-SIZE: 11pt" color="#666666"> 因质量偏心所引起的振动会随转速加快而剧增,因此经静平衡过的砂轮在高速研磨作业时仍然会产生相当的振动,同时砂轮安装时与主轴的间隙及砂轮气孔中研磨液的吸附,也会增添附加的不平衡,另外砂轮在研磨过程中的摩耗与修整,使得初始砂轮的静平衡状态渐趋恶化。 </font></span></p>

<p style="MARGIN-TOP: 0pt; MARGIN-BOTTOM: 0pt" class="p0"><font color="#666666"><span style="FONT-FAMILY: 宋体; FONT-SIZE: 11pt"> </span></font><span style="FONT-FAMILY: 宋体"><font style="FONT-SIZE: 11pt" color="#666666"> 所以,不论再好再精密的磨床与砂轮,如果缺少实时的在线动平衡校正,都很难确保持续且稳定的研磨精度与质量。</font><font style="FONT-SIZE: 11pt" color="#0000ff">砂轮线上动平衡校正仪不需要卸下砂轮,在磨床上调整砂轮平衡块来做动平衡校正。</font></span></p>

</td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"><span style="FONT-FAMILY: 宋体; COLOR: #ff0000; FONT-SIZE: 9pt; FONT-WEIGHT: 700">砂轮线上动平衡仪广泛应用:平面磨床、外圆磨床、无心磨床、光学投影磨床、磨齿磨床、专用研磨机等</span></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%"><img border="0" width="332" height="227" alt="" src="http://www.honfusen.com/yphoto.files/IMG0306A.jpg" /></td>

<td height="100%" valign="top" width="50%"><img border="0" width="327" height="230" alt="" src="http://www.honfusen.com/yphoto.files/IMG0504A.jpg" /></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%"><font color="#666666" size="2"><span style="FONT-FAMILY: 宋体">砂轮动平衡仪在大型无心磨床上的应用</span></font></td>

<td height="100%" valign="top" width="50%"> </td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%"><img border="0" width="332" height="283" alt="" src="http://www.honfusen.com/yphoto.files/IMG0501A.jpg" /></td>

<td height="100%" valign="top" width="50%"><img border="0" width="330" height="283" alt="" src="http://www.honfusen.com/ynews.files/砂轮线上动平衡.jpg" /></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%"><font color="#666666" size="2"><span style="FONT-FAMILY: 宋体">砂轮线上动平衡仪在齿轮加工磨床应用</span></font></td>

<td height="100%" valign="top" width="50%"> </td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%"><img border="0" width="331" height="309" alt="" src="http://www.honfusen.com/yphoto.files/M9015-optmachine.jpg" /></td>

<td height="100%" valign="top" width="50%"><img border="0" width="327" height="308" alt="" src="http://www.honfusen.com/yphoto.files/大砂轮.jpg" /></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"><font color="#666666" size="2"><span style="FONT-FAMILY: 宋体">砂轮动平衡仪在光学投影磨床应用,光学投影磨床转速高要求动平衡精度高,可以校到0.002um振动。</span></font></td>

</tr>

<tr height="100%">

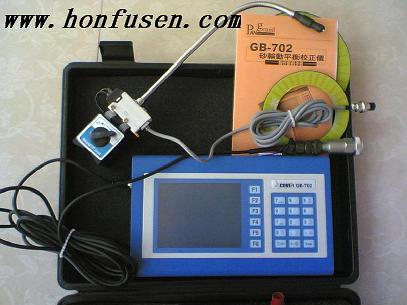

<td height="100%" valign="top" width="100%" colspan="2"><span class="shadow-ptname1"><strong><font color="#666666" size="2"><span style="FONT-FAMILY: MS Sans Serif" lang="EN-US">图解应用GB-702 </span></font><font color="#666666"><span style="FONT-FAMILY: 宋体; FONT-SIZE: 10pt" lang="EN-US">携带式砂轮在线动平衡校正仪校正精密磨床</span></font></strong></span></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%">

<table id="table184" border="0" cellspacing="2" cellpadding="0" width="100%">

<tbody>

<tr>

<td class="style48" height="24" width="249"><font color="#666666"><img border="0" width="320" height="264" alt="" src="http://www.honfusen.com/yapplication.files/振动传感器放置位置.jpg" /></font></td>

</tr>

</tbody>

</table>

</td>

<td height="100%" valign="top" width="50%">

<table id="table185" border="0" cellspacing="2" cellpadding="0" width="100%">

<tbody>

<tr>

<td class="style48" height="24" width="249"><font color="#666666"><img border="0" width="324" height="263" alt="" src="http://www.honfusen.com/yapplication.files/应用刀具磨床.jpg" /></font></td>

</tr>

</tbody>

</table>

</td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"><font color="#666666" size="2"><span style="FONT-FAMILY: 宋体">架设振动传感器:吸附在近砂轮主轴正上方或是主轴侧方,以上应用曲轴外圆磨床 。<strong>(量测振动)</strong></span></font></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="50%">

<table id="table182" border="0" cellspacing="2" cellpadding="0" width="100%">

<tbody>

<tr>

<td class="style48" height="24" width="249"><font color="#666666" size="2"><strong><span style="FONT-FAMILY: 宋体"><img border="0" width="314" height="232" alt="" src="http://www.honfusen.com/yapplication.files/光传感器防止位置.jpg" /></span></strong></font></td>

<td class="style48" height="24"> </td>

</tr>

</tbody>

</table>

</td>

<td height="100%" valign="top" width="50%">

<table id="table183" border="0" cellspacing="2" cellpadding="0" width="100%">

<tbody>

<tr>

<td class="style48" height="24" width="309"><font color="#666666" size="2"><strong><span style="FONT-FAMILY: 宋体"><img border="0" width="320" height="230" alt="" src="http://www.honfusen.com/yapplication.files/校正中.jpg" /></span></strong></font></td>

<td class="style48" height="24">

<p> </p>

<p> </p>

<p> </p>

<p> </p>

<p> </p>

<p> </p>

</td>

</tr>

</tbody>

</table>

</td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"><font color="#666666" size="2"><span style="FONT-FAMILY: 宋体">贴上反光纸片裁减5mm正方形大小,贴于砂轮或是圆盘侧面。红外线光传感对准反光贴纸6CM处。<strong>(量测转速)</strong></span></font></td>

</tr>

<tr>

<td height="100%" valign="top" width="49%"><font color="#666666" size="2"><span style="FONT-FAMILY: 宋体"><img border="0" width="160" height="225" alt="" src="http://www.honfusen.com/yapplication.files/IMG0244A.jpg" /><img border="0" width="133" height="202" alt="" src="http://www.honfusen.com/yphoto.files/指示灯.jpg" /></span></font></td>

<td height="100%" valign="top" width="48%"><font color="#666666" size="2"><span style="FONT-FAMILY: 宋体"><img border="0" width="322" height="226" alt="" src="http://www.honfusen.com/yapplication.files/Image(180).jpg" /></span></font></td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"><font color="#666666" size="2"><span style="FONT-FAMILY: 宋体">手动转动砂轮当传感器上红灯,绿灯交互闪烁为正确距离。</span></font></td>

</tr>

<tr>

<td height="100%" valign="top" width="50%"><font color="#666666"><img border="0" width="328" height="227" alt="" src="http://www.honfusen.com/yphoto.files/动平衡1.jpg" /></font></td>

<td height="100%" valign="top" width="50%"><font color="#666666"><img border="0" width="328" height="228" alt="" src="http://www.honfusen.com/yphoto.files/动平衡2.jpg" /></font></td>

</tr>

<tr>

<td height="100%" valign="top" width="100%" colspan="2"><font color="#666666">按下新做动平衡,将平衡块放在0.120.240度三个位置,启动砂轮,仪器会自动量测。</font></td>

</tr>

<tr>

<td height="100%" valign="top" width="50%"><font color="#666666"><img border="0" width="326" height="246" alt="" src="http://www.honfusen.com/yphoto.files/显示数据.jpg" /></font></td>

<td height="100%" valign="top" width="50%"><font color="#666666"><img border="0" width="276" height="246" alt="" src="http://www.honfusen.com/yphoto.files/法兰平衡块.jpg" /></font></td>

</tr>

<tr>

<td height="100%" valign="top" width="100%" colspan="2"><font color="#666666">根据仪器显示,移动砂轮法兰盘处三个平衡块,(如果法兰处没有刻度,仪器自带刻度纸可贴上,参考刻度)</font></td>

</tr>

<tr>

<td height="100%" valign="top" width="50%"><img border="0" width="333" height="221" alt="" src="http://www.honfusen.com/yphoto.files/34.jpg" /></td>

<td height="100%" valign="top" width="50%"><img border="0" width="319" height="218" alt="" src="http://www.honfusen.com/yphoto.files/35.jpg" /></td>

</tr>

<tr>

<td height="100%" valign="top" width="100%" colspan="2">平衡块移动好后启动磨床,检测振动由8.4um降低至0.076um。如需要精度再次提高如右图所示需要在次稍微移动平衡块。</td>

</tr>

<tr>

<td height="100%" valign="top" width="50%"><img border="0" width="332" height="241" alt="" src="http://www.honfusen.com/yphoto.files/GB-7021.jpg" />

<p>以上事列为部分磨床动平衡校正说明。根据GB-702仪器显示的数据调整砂轮平衡块,一般调整三次左右就可以把磨床的振动降下来,非常高效方便,熟练者在6分7分钟左右就可完成。此仪器是精密研磨加工业者必不可少的法宝。<br />

<br />

更详细说明请见说明书,或是需要行销人员现场演示。 请联络:<font color="#0000ff"><strong>手机:13911901007 电话: 010-51669481</strong></font></p>

</td>

<td height="100%" valign="top" width="50%">

<table id="table193" border="0" cellspacing="2" cellpadding="0" width="100%">

<tbody>

<tr>

<td class="style48" height="24" width="249"><img border="0" width="312" height="376" alt="" src="http://www.honfusen.com/ynews.files/便携式砂轮动平衡仪.jpg" /></td>

</tr>

</tbody>

</table>

</td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2"> </td>

</tr>

<tr height="100%">

<td height="100%" valign="top" width="100%" colspan="2">

<p align="left"><font color="#ff0000"><strong>据美国振动研究权威机构,IRD公司多年机床维修经验值推荐: </strong></font><br />

<font color="#666666"><span class="style11"><span style="FONT-FAMILY: 宋体; LETTER-SPACING: 1px; FONT-SIZE: 9pt">为确保磨床加工精度,主轴轴承外壳处测得的许可振动位移量(峰-峰值)应控制如下:</span></span></font><br />

<br />

<span class="style11"><span style="FONT-FAMILY: 宋体; LETTER-SPACING: 1px; FONT-SIZE: 9pt"><font color="#0000ff"><strong> 磨床 许可振动量范围:</strong><br />

<br />

螺丝磨床: 0.25-1.50um<br />

齿轮磨床: 0.25-1.50um<br />

成型轮廓磨床:0.75-2.00um<br />

内外圆磨床: 0.75—2.50um<br />

无心磨床: 0.75-2.50um<br />

平面磨床: 0.75-3.50um<br />

双端面磨床: 1.20-5.00um</font></span></span></p>

</td>

</tr>

</tbody>

</table>

</p> |